|

詳細情報 |

|||

| 製品名: | 実験室振動ボールミール | 型番: | ZM-2 |

|---|---|---|---|

| 電圧: | 380V | パワー: | 1.1kw |

| 総量: | 2L | 最大積載量: | 1L |

| ハイライト: | 0.5L-5L 振動型ラボボールミル,高周波振動型ラボボールミル,金属セラミック粉末用振動型ボールミル |

||

製品の説明

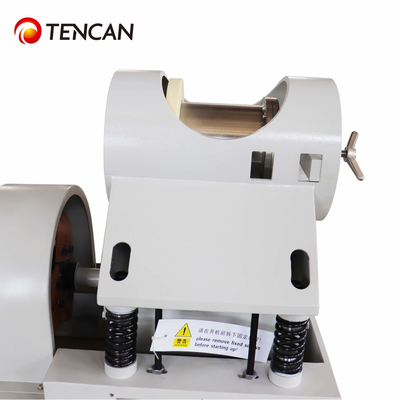

Tencan ZM-2 研究所用振動ボールミル 0.5L-5L 金属セラミック粉末用高周波粉砕

ラボ振動ボールミルの概要

ラボ振動ボールミルは、振動ミルとしても知られ、革新的な高効率粉末処理システムです。この高度な装置は、シングルシリンダー、ダブルシリンダー、トリプルシリンダーの3つの構成で利用できます。優れた性能を発揮するように設計された当社のラボ振動ボールミルは、卓越した操作の簡便性、信頼性の高い機能性、容易なメンテナンス、およびゼロ汚染排出による優れた環境適合性を提供します。このシステムは、乾式および湿式粉砕プロセスの両方をサポートしており、オプションのシリンダーライナーには、304/316Lステンレス鋼、高純度アルミナセラミック(99.5% Al₂O₃)、イットリア安定化ジルコニア(3Y/5Y-ZrO₂)、エンジニアリングプラスチック(ナイロン、PTFE)、食品グレードのポリウレタン/PP/PE材料が含まれます。

ラボ振動ボールミルの動作原理

振動ボールミルシステムは、強化フレーム、高耐久性シャーシ、精密振動励起器、粉砕シリンダーアセンブリ、ダンピングスプリング、および高トルクモーターで構成されています。動作中、モーターは偏心振動子を駆動して高周波振動運動(通常800〜3000 RPM)を生成し、粉砕室内に強烈な微小振幅振動(1〜10mm)を発生させます。この作用により、粉砕媒体の複雑な三次元運動が誘発され、強力な衝撃、せん断、摩擦力が生じ、以下を通じて超微粒子化が達成されます。

連続的な高エネルギー衝突

効率的な表面摩耗

均一な粒子分散

ラボ振動ボールミルの用途

この多用途の粉砕システムは、複数の業界で広く使用されています。

高度電子機器:MLCC誘電体粉末、フェライトコア

セラミックエンジニアリング:テクニカルセラミックス、構造セラミックス

化学処理:触媒、無機顔料

粉末冶金:タングステンカーバイド、金属合金粉末

医薬品:API微粉化、ドラッグデリバリーシステム

特殊材料:量子ドット、グラフェン複合材料、バッテリー材料

Tencanラボ振動ボールミルの特徴

Tencanラボ振動ボールミルの技術パラメータ

| ラボ振動ボールミルの技術パラメータ | ||||||

| 型番 | 総容量 | 最大負荷容量 | 電源 | 利用可能なバレル | 供給サイズ | 出力粒度 |

| ZM-1 | 1L | 0.50L | 380V/1.1KW | ステンレス鋼 ナイロン コランダム PTFE |

≤5mm | ≤1μm |

| ZM-2 | 2L | 1.00L | 380V/1.1KW | ≤5mm | ≤1μm | |

| ZM-3 | 3L | 1.50L | 380V/1.1KW | ≤5mm | ≤1μm | |

| ZM-5 | 5L | 2.50L | 380V/1.1KW | ≤5mm | ≤1μm | |

利用可能なミルジャー:ステンレス鋼ミルジャー、アルミナセラミックミルジャー、ジルコニアミルジャー、瑪瑙ミルジャー、タングステンカーバイドミルジャー、PUミルジャー、ナイロンミルジャー、PTFEミルジャーなど。

![]()

| ミルジャーと材料に関する推奨ソリューション | |

| 材料のカテゴリ | 推奨ミルジャー |

| 土壌およびその他の不純物が許容されない材料 | 瑪瑙ミルジャー |

| 不純物が許容されない金属および非金属材料 | ジルコニアミルジャー |

| ダイヤモンド、タングステンカーバイドなどの高硬度材料 | タングステンカーバイドミルジャー |

| 強酸および強アルカリ材料または高温下のその他の材料 | PTFEミルジャー |

| 不純物に対する感度が低い鉄鉱石材料 | 304ステンレス鋼ミルジャー |

| 高温下での後処理を行う顔料またはその他の材料 | ナイロンミルジャー |

| セラミック釉薬などのアルミニウム材料 | コランダムミルジャー |

| リチウム電池などの電子材料 | ポリウレタンミルジャー |

| 容易に酸化される材料または特殊雰囲気下で保護する必要がある特殊材料 特別な雰囲気下で保護する必要がある |

真空ミルジャー |

| 粉砕媒体と材料に関する参考文献 | ||

| 材料 粉砕媒体 |

硬度 (モース) |

特徴 |

| ジルコニアボール | ≥9.0 | 超耐摩耗性、不純物なし、耐食性、耐高温性。 |

| ステンレス鋼ボール | ≥6.0 | 耐摩耗性、一般的な耐食性、耐高温性。 |

| 瑪瑙ボール | ≥7.0 | 超耐摩耗性、金属で汚染されてはならない医薬品、食品、その他の材料に使用、耐食性、耐高温性。 |

| アルミナボール | ≥8.5 | 耐摩耗性、耐食性、耐高温性。 |

| タングステンカーバイドボール | ≥9.0 | 超耐摩耗性、不純物なし、耐食性、耐高温性。 |

| ミルジャーとボールのマッチングソリューション | |||||

| 項目 | 瑪瑙ボール | アルミナボール | ステンレス鋼ボール | ジルコニアボール | タングステンカーバイドボール |

| 瑪瑙ミルジャー | √ | ||||

| コランダムミルジャー | ▲ | √ | ▲ | ||

| ステンレス鋼ミルジャー | √ | ||||

| ジルコニアミルジャー | ▲ | √ | |||

| ナイロンミルジャー | ▲ | √ | |||

| PTFEミルジャー | √ | ▲ | |||

| ポリウレタンミルジャー | √ | ▲ | |||

| タングステンカーバイドミルジャー | ▲ | √ | |||

| √ は:最も適していることを意味します ▲ は:適していることを意味します | |||||