|

詳細情報 |

|||

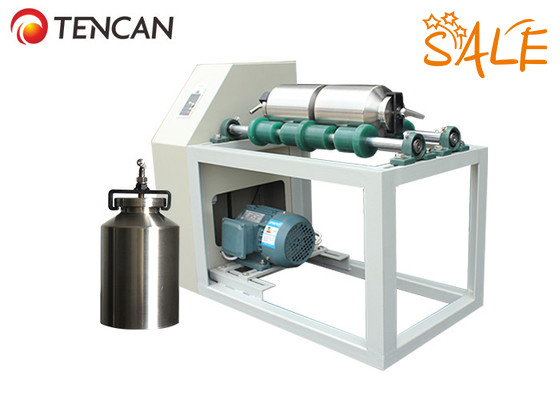

| 製品名: | 横のロール瓶の製造所 | モデルNO: | GQM-2-5 |

|---|---|---|---|

| 仕事 の 位置: | 2 ポジション | 総容積: | 10L |

| 最大容量: | 3.33L | 回転速度: | 50-410のrpm |

| 電圧: | 220V-50Hzから110V-60Hzまで | パワー: | 0.37KW |

| ハイライト: | 2*5L ホリゾナルロール・ジャー・ミル |

||

製品の説明

2*5L水平ロールボトルミール 実験室/小批量生産のための高効率のミクロン粉末磨きと混合

概要:

ホリゾンタル・ロール・ジャー・ミル (Horizontal Roll Jar Mill) は,実験室や小規模生産環境での超細微な研磨と混合のために設計された精密粉末研磨機である.複数のポジションのロールボールミルとしても知られており,材料の効率的な並列加工のために2つの5Lボトルを持っています.

主要 な 利点:

✔超細磨 微米レベルの粉末一貫性を向上させる.

✔コンパクト&ユーザーフレンドリー タイム制御,一時停止機能,累積タイムで簡単な操作

✔電子/磁気材料,セラミック,金属粉末,医薬品,研究開発に最適

✔耐久性設計 耐磨性のあるゴムロールと均質な粒子の分散のために最適化された回転速度が特徴です

✔柔軟な操作 連続または間歇的な磨きをサポートし,実験室または小批量ニーズに合わせてカスタマイズできます.

作業原理:

材料と磨き媒体は回転力によって引き上げ,落として,衝撃,摩擦,切断力による効率的な粉砕を保証します.砂球の傾斜流動は,ミクロンレベルの均質な粉末出力を保証します.

理想的な:

電子・磁気材料

薬学と生物医学研究

セラミック・グラス&金属合金粉末

ナノ材料と高度な複合材料

精度,効率,信頼性を向上させる!

テクニカルパラメータ

| ローリング・ジャー・ラボ・ボール・ミルの技術パラメータ | |||||

| カテゴリー | サイズ/WT (mm) |

モデル番号 | モーター パワー (kW) |

電圧 | 回転速度 (rpm) |

| 2 作業ステーション | 950*480*685mm/59kg | GQM-2-5 | 0.37 | 220V-50Hz/60Hz | 50〜410 |

| 1130*550*690mm/80kg | GQM-2-15 | 1.1 | 220V-50Hz/60Hz | 40~365 | |

| 13506550*690mm/92kg 試料用 | GQM-2-20 | 1.5 | 220V-50Hz/60Hz | 40~365 | |

| 4 作業ステーション | 950*660*690mm/70kg | GQM4-5 単層 |

0.75 | 220V-50Hz/60Hz | 50〜410 |

| 950*480*870mm/92kg | GQM4-5 二重層 |

0.75 | 220V-50Hz/60Hz | 50〜410 | |

| 1130*800*690mm/95kg | GQM-4-15 | 1.5 | 220V-50Hz/60Hz | 40~365 | |

| 1350*820*690mm/122kg | GQM-4-20 | 2.2 | 380V-50Hz/60Hz | 40~340 | |

| 8 作業ステーション | 950*660*960mm/106kg | GQM-8-5 | 1.5 | 220V-50Hz/60Hz | 50〜410 |

| 1130*800*690mm/152kg | GQM-8-15 | 2.2 | 380V-50Hz/60Hz | 40~365 | |

ロールミルの器具

ローリングボールミール機に加えて,我々は,ロールミールボトルのようなすべての種類の提供 ステンレス鋼ミールボトル,ジルコニアミールボトル,アルミナセラミックミールボトル,ナイロンミールボトル,PUミールボトル,PTFEミールボトル,ほかさらに,私たちはステンレス鋼ミールボール,ジルコニアミールボール,アルミナミールボール,アゲートミールボール,タングスタムミールボールなども提供しています.

![]()

| ミールボトルと材料に関する対応ソリューションに関する勧告 | |

| 材料のカテゴリー | 推薦 の ミル 容器 |

| 土と他の 汚れのある物質は許されない | アガート・ミール・グラス |

| 金属と非金属材料は,不純物を含めて使用は許されない. | シルコニアミールボトル |

| ダイヤモンドやウォルフレムカービッドのような高硬度材料 | タングランカルビッドミールボトル |

| 強い添加物や高温のアルカリ性物質や他の材料 | PTFEミールボトル |

| 汚れに対する感度が低い鉄鉱石材料 | 304 ステンレス鋼製 工場用瓶 |

| 高温で後処理された色素または他の材料 | ナイロン製のガラス |

| 陶器のグラスなどのアルミニウム材料 | コルンドム・ミール・ボトル |

| リチウム電池のような電子材料 | ポリウレタンミールボトル |

| 簡単に酸化される材料や, 特殊な大気下で保護されます |

バキュームミルのボトル |

![]()

| 磨きメディアと材料に関する参考文献 | ||

| 材料 磨き媒体 |

硬さ (モフス) |

特徴 |

| シルコニア球 | ≥90 | 超耐磨性 汚れや腐食 耐高温 |

| ステンレス鋼のボール | ≥60 | 耐磨性 腐食性 高温性 |

| アガート玉 | ≥70 | 超耐磨性 薬物,食品,金属に汚染されず,腐食や高温に耐える材料に使われます |

| アルミナボール | ≥85 | 耐磨性,腐食性,高温性 |

| ワルフタンカービッドのボール | ≥90 | 超耐磨性 汚れや腐食 耐高温 |

| ミル 容器 と ボール の 対応 ソリューション | |||||

| ポイント | アガート玉 | アルミナボール | ステンレス鋼のボール | シルコニア球 | ワルフタンカービッドのボール |

| アガート ミル グラス | √ | ||||

| コルンドム・ミル・グラス | ▲ | √ | ▲ | ||

| ステンレス鋼のミールボトル | √ | ||||

| ジルコニアミールボトル | ▲ | √ | |||

| ナイロンミールボトル | ▲ | √ | |||

| PTFEミールボトル | √ | ▲ | |||

| ポリウレタンミールボトル | √ | ▲ | |||

| ワルフタン・カービッド・ミール・グラス | ▲ | √ | |||

| √ 最も適したという意味 ▲ 適したという意味 | |||||

この製品の詳細を知りたい